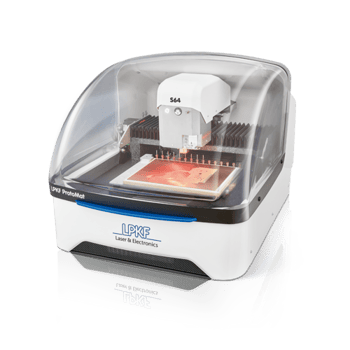

LPKF ProMask and LPKF ProLegend

Brand :

LPKF Laser & Electronics SE

Categories :

Research and In-house PCB Prototyping

In-house system for solder resist mask application and legend printing

- Compact, fast and simple

- Optimum soldering

- Professional lettering

- Four simple steps

Specifications

LPKF offers two processes for the professional surface finish of printed circuit boards: Solder resist with LPKF ProMask and assembly printing with LPKF ProLegend.

Solder mask and legend printing for in-house prototyping

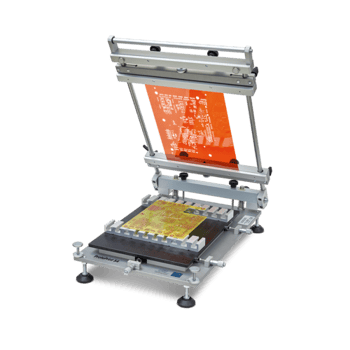

The solder resist is - especially with SMT components - a basic requirement for safe soldering. With LPKF ProMask, a professional solder resist mask can be quickly and effectively applied to already structured circuit boards.

The solder resist mask is printed from the CAD program onto a transparent foil, transferred to the printed circuit board and developed. In just four steps, the structured circuit board is given a perfect surface finish in just a few minutes for soldering without short circuits.

The legend printing follows the same principle: ProMask and ProLegend are supplied with all necessary tools and consumables for a perfect result.

LPKF ProMask and LPKF ProLegend are essential for fast, simple and cost-effective PCB prototyping or small series production. A photographic exposure process transfers all structures or lettering exactly to the printed circuit board.

The advantages of LPKF ProMask:

Fast, simple and cost-effective

Clean electrical insulation

Perfect protection of the printed circuit board against corrosion and oxidation

The advantages of LPKF ProLegend:

High adhesive strength against cleaning agents

Simple procedure like LPKF ProMask

Minimum letter height of 2 mm