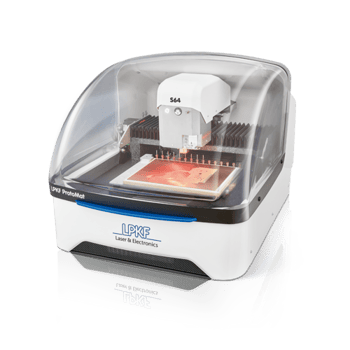

LPKF MultiPress S4

Brand :

LPKF Laser & Electronics SE

Categories :

Research and In-house PCB Prototyping

Press for Multilayer Production

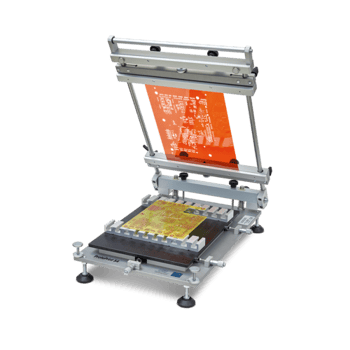

- In-house production of multilayer prototypes with rigid, rigid flex, flexible and RF materials

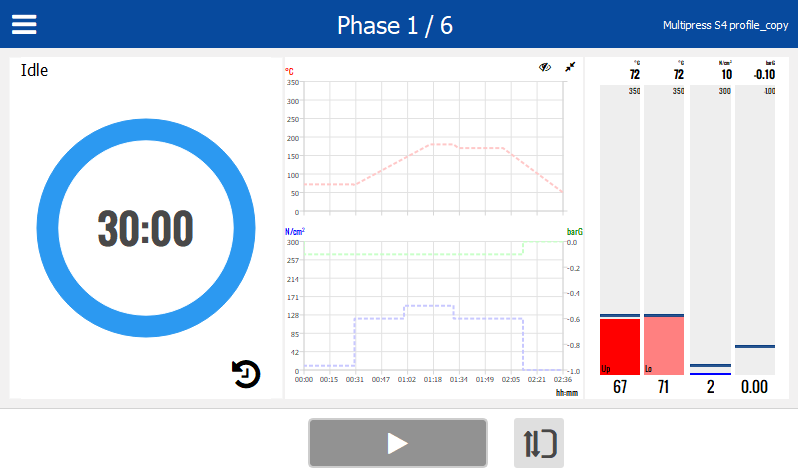

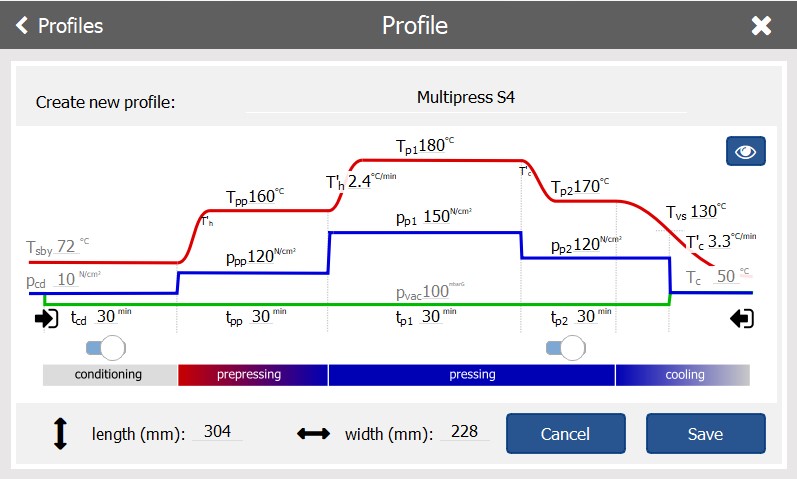

- Advanced intuitive graphical user interface with touch screen controls and guidance

- Up to five freely programmable temperature/pressure process steps

- Vacuum function and fume exhaust

- Stand-alone design; easily moveable on wheels

Specifications

Multilayer PCB prototypes with 8 layers

The LPKF MultiPress S4 presses multilayer circuits from rigid, rigid-flex and flexible PCB materials. Process control provides for a homogeneous material compound. Efficient heat dissipation assures short cooling phases. The result is optimum process times.

A high packing density and the corresponding high number of circuits or additional tasks that need to be performed by the circuit board require a multilayer design of complex prototypes which can accommodate circuits in several layers.

The new concept with an intuitive graphical user inter-face offers an easy entry to multilayer production for a novice and opens up possibilities for setting up the process for next-generation materials. The three to five step process with different ramp-controlled tempera-tures and pressures can also utilize vacuum and rapid cooling.

The single-phase operation, built-in vacuum and hyd-raulic pump, connectivity, and predefined process setups for common materials make the stand-alone LPKF MultiPress S4 the most efficient system for multi-layer pressing in your own lab. Any fumes or odors can be removed directly via an exhaust connection to the ventilation system.