Furnace Thermography

Optimizing efficiency and performance in fired heaters

Specializing in thermography services for the petrochemical industry

Has developed state-of-the-art methodologies for diagnosing fired heaters

We measure accurate tube temperatures

And we do much more than that. (We do not replace thermocouples; Thermocouples can never replace what we do; Thermocouples are active all the time, but can only give readings from single spots; Thermography gives information about the whole furnace interior)

It is necessary to understand how the furnace works (Problems and their sources and patterns)

We have developed methods and knowledge to do a real diagnosis

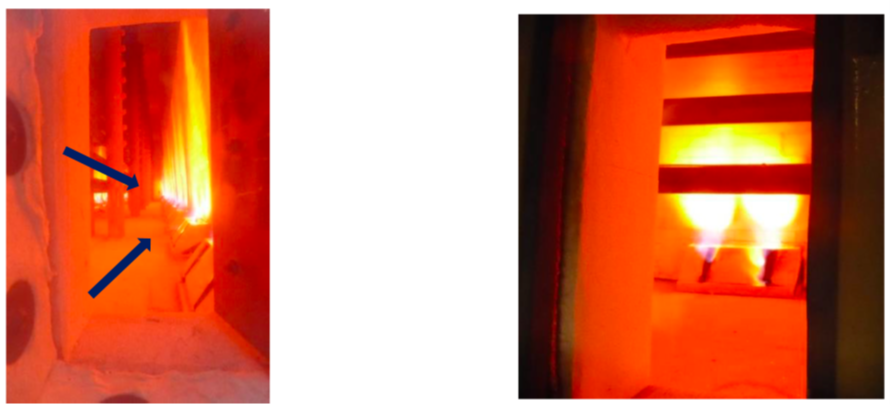

Balanced heating (Making sure the heat is applied evenly in the whole furnace; prevents damage and lost production)

Baseline (Enables comparison with a known condition, improves analysis)

Look at the whole furnace, not just the tubes.

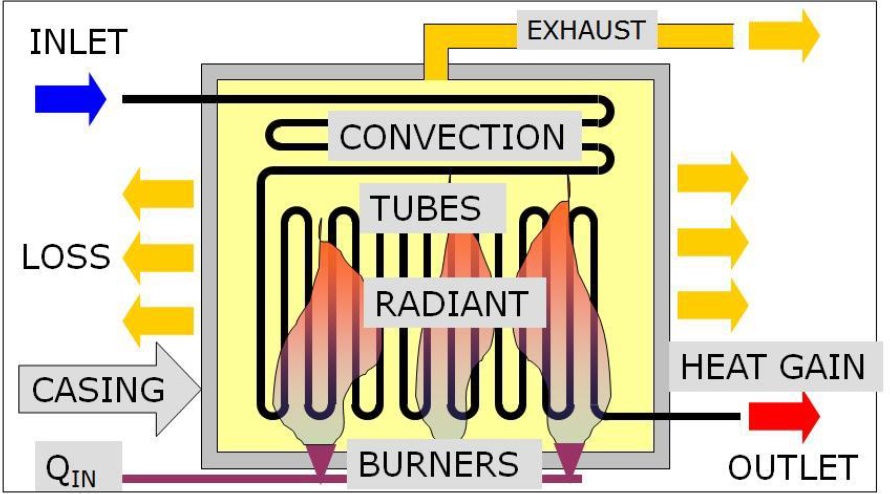

Figure 1. The thermal balance of a furnace. Energy from fuel is put in, the process fluid gains some of the heat and the rest is lost through the furnace wall and the exhaust.

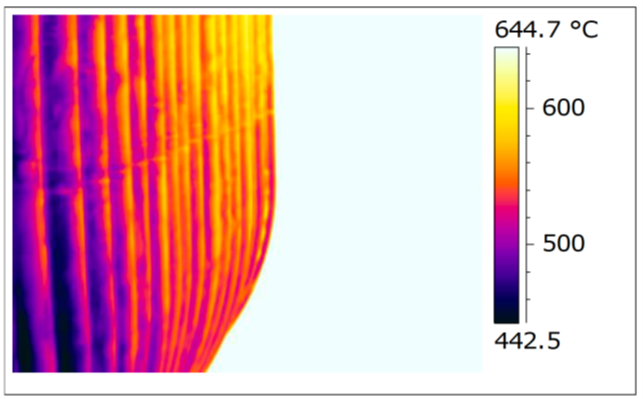

Figure 2, FLIR GF309, 24º lens

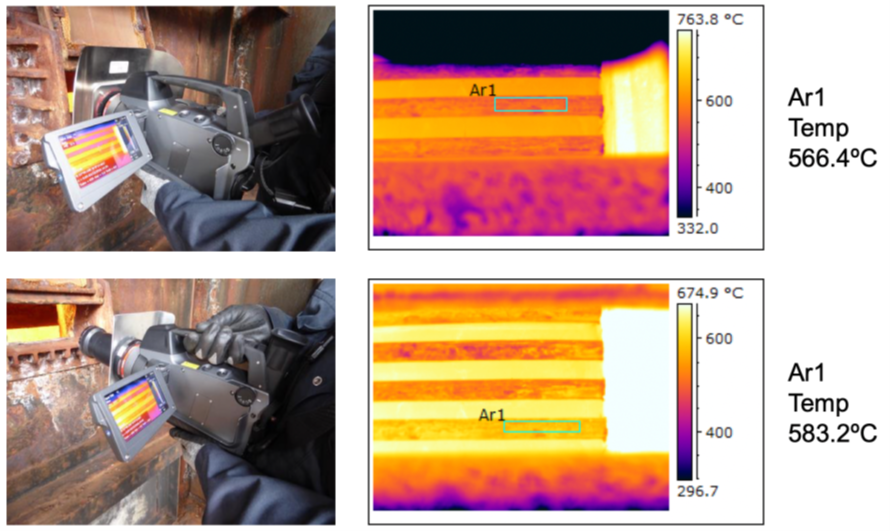

Fig 3: The extender provides a wider field of view, which enables to “see” more tubes and a more accurate temperature measurement through the peephole

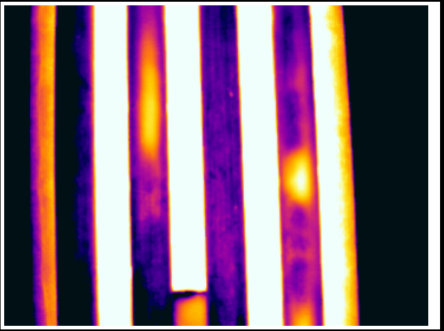

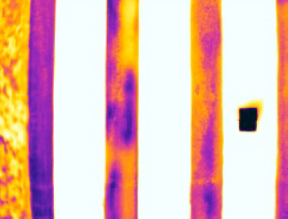

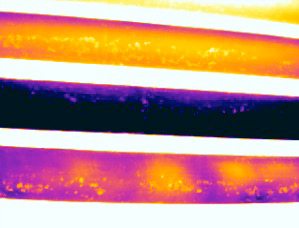

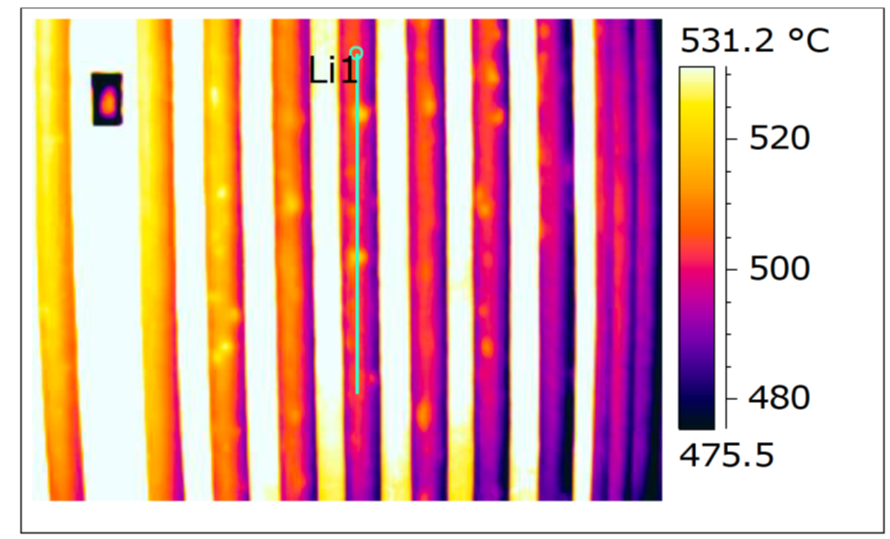

Figure 4 , example of coking

Figure 5, giraffe neck signature, sign of coking

Figure 6, sign of mild local coking

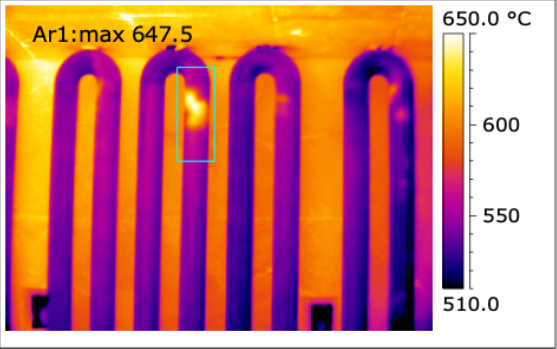

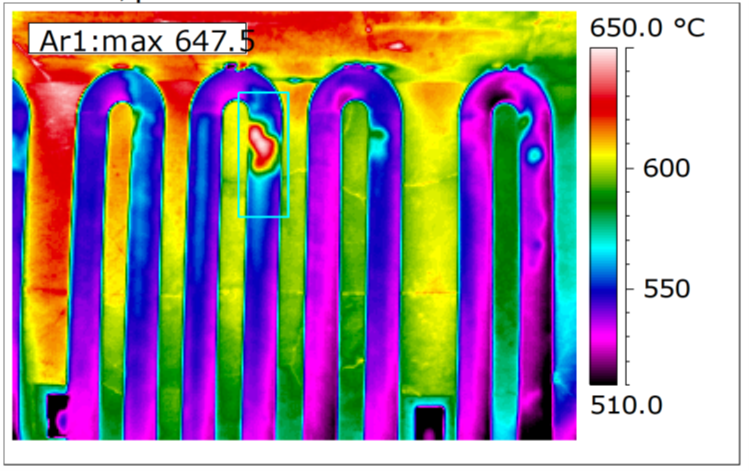

Fig 7.1 Different Color pallets, Same spot and time

Fig 7.2 Different Color pallets, Same spot and time

Fig 8 Example of coking

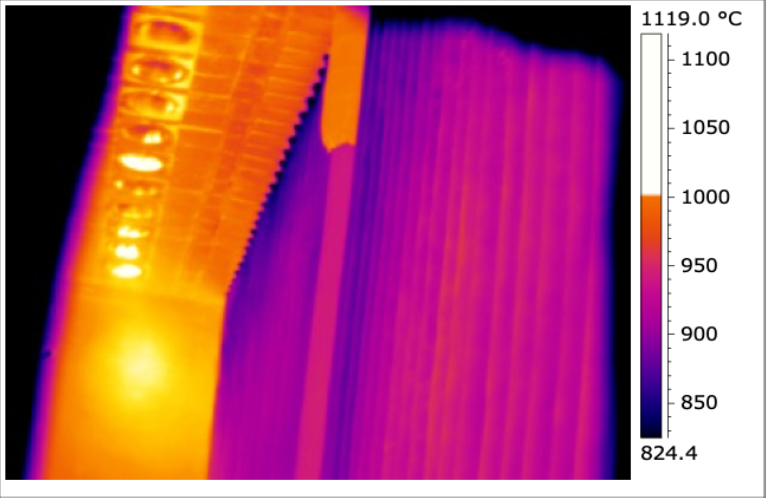

Figure 9, Some Burners are off and some are partly blocked. This causes a disturbed convection behavior in the reformer

Figure 10, Most of the burners burn evenly. Some show a more divergent burning pattern, which seems to be due to an excess of primary fuel

Figure 11, Burners low and off

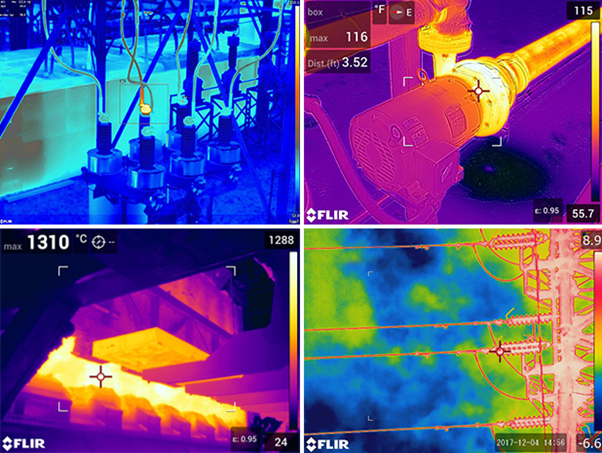

Electrical Thermography Inspection Services

We provide electrical thermography services for Switch Gear, Service Disconnects, Transfer Switches, Bus Runs, Motor Control Centers, Breaker Panels, Starters, chillers and Roof top HVAC Equipment, VFD’s

It makes it possible to conduct electrical thermal imaging surveys with no intrusion.

Reduce Unscheduled downtime

It assures safety by detecting electrical problems in good time and avoiding fires caused by overloaded circuits or faulty wiring

Noise Survey

Noise survey is conducted in areas where noise exposure is likely to be hazardous. Noise level refers to the level of sound. A noise survey involves measuring noise level at selected locations throughout an entire plant or sections to identify noisy areas. This is usually done with a sound level meter (SLM).

Portable Appliance Testing (PAT) Testing

Portable Appliance Testing (PAT) provides evidence that electrical appliances and equipment are safe to use. Portable Appliance Testing (PAT Testing) involves conducting an assessment of any movable electrical appliance.

This often involves testing and recording results for 000’s of items within an organisation; from computers, printers and telephones in an office through to machinery in workshops, warehouses and factories and kitchen equipment.

Our focus is on minimising disruption to your workplace. Ahead of undertaking any testing, acit will work with you to provide a bespoke testing solution that is flexible to your business needs; as each item needs to be unplugged in order to test it, acit offer an out-of-hours or out-of-term testing service at no extra charge or the option to work within your scheduled downtime.

We use the latest testing instruments to record all test data and automatically download test data into our advanced database software, offering maximum efficiency and accuracy.

PAT testing ensures the safety of your employees and visitors. Any items that fail a PAT test can be repaired, replaced or removed from service for safety, and a full written fail report will be issued to you. We will advise you on future testing schedules, depending on your type of equipment and environment.

This type of testing is does ensure that you are compliant with Health and Safety regulations

Light Testing

A light meter (also known as an illuminance metre or lux meter) is used by lighting professionals to measure the quantity of light in an area or on a specific work surface. A sensor on the light metre monitors the amount of light falling on it and provides the user with a measured illuminance reading.

Partial Discharge

In addition to defect identification, partial discharge testing offers several advantages over other testing methods with the primary advantage being that the test is a non-destructive test as it does not result in the device under test being stressed to failure, thereby it does not affect the existing insulation capability of the component.

Temperature Mapping

A temperature-mapping exercise is required for any space allocated for the storage and handling of products with a specified labelled storage temperature. This includes freezer rooms, cold rooms, temperature-controlled storage areas, quarantine areas and receiving and loading bays. It may also include laboratories.